Piezo Solutions

10072 Crows Nest Cove

Aurora, Ohio 44202

Phone: (216) 406-2045

Email: piezosolutions@outlook.com

10072 Crows Nest Cove

Aurora, Ohio 44202

Phone: (216) 406-2045

Email: piezosolutions@outlook.com

About Us

Piezo Solutions provides Engineering Support and Product Development for both New and Existing Products and Applications.

Customers new designs see the quickest times to market with the highest quality and reliability.

Piezo Solutions extensive knowledge and experience of materials and processes helps manufactures improve yields and quality on existing designs while reducing costs, leadtime and inventory.

Most companies, that use piezoelectric components in their products, have little knowledge of how a piezoelectric component works or even how to specify it, test it and handle it.

Most manufactures of piezoelectric materials have very little knowledge of how their piezoelectric materials function in their customers products.

Piezo Solutions has over 45 years of doing both manufacturing piezoelectric components and also using these elements in assemblies.

We also do customised training at your facilities so that Engineering knows what to specify, Purchasing knows what to order and Manufacturing knows how to handle, clean, solder and bond to piezoelectric ceramic elements.

Our job is to make our customers successful and....... we take that very seriously!

Customers new designs see the quickest times to market with the highest quality and reliability.

Piezo Solutions extensive knowledge and experience of materials and processes helps manufactures improve yields and quality on existing designs while reducing costs, leadtime and inventory.

Most companies, that use piezoelectric components in their products, have little knowledge of how a piezoelectric component works or even how to specify it, test it and handle it.

Most manufactures of piezoelectric materials have very little knowledge of how their piezoelectric materials function in their customers products.

Piezo Solutions has over 45 years of doing both manufacturing piezoelectric components and also using these elements in assemblies.

We also do customised training at your facilities so that Engineering knows what to specify, Purchasing knows what to order and Manufacturing knows how to handle, clean, solder and bond to piezoelectric ceramic elements.

Our job is to make our customers successful and....... we take that very seriously!

Customer Products and Applications

3M Touchscreen Systems - Piezoelectric Sensors for very large Touchscreens

BAE Aerospace - Missile & Aircraft Gyros and Accelerometers

Cleveland Clinic - Handheld Corneal Thickness Ultrasonic Scanner

Condor Pacific - Missile & Aircraft Gyros and Accelerometers

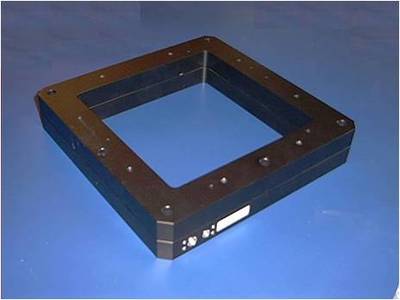

DuPont / Toppan Photomask - Physik Instrumente Piezoelectric Stage Assembly Repair

Erasmus University Rotterdam - Training of NextGen Piezoelectric Materials

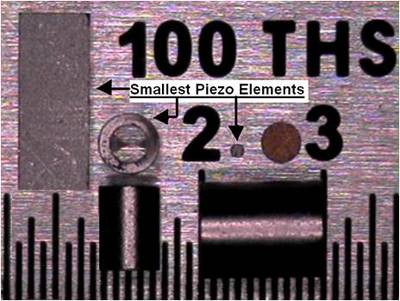

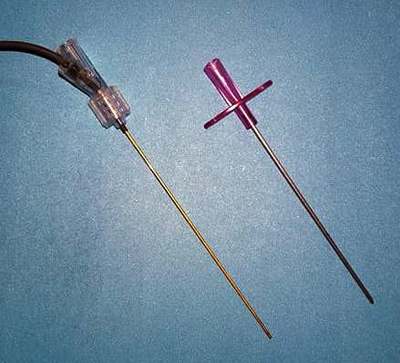

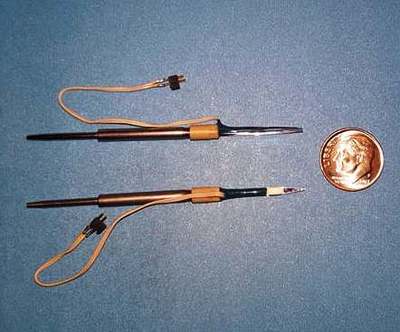

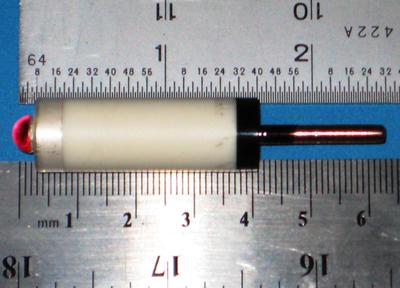

Escalon Medical / Vascular Solutions - Worlds Smallest Micromachined 200micron SmartNeedle Sensors

Ethicon Endo-Surgery / Ultracision - Ultracision and Harmonic Scalpel Development

GE Medical Imaging - Medical Imaging Transducer Materials and Process Development

Gilardoni SPA (Lake Como, Italy) - NDT Transducer Product and Process Development

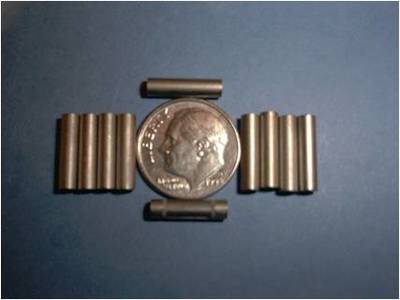

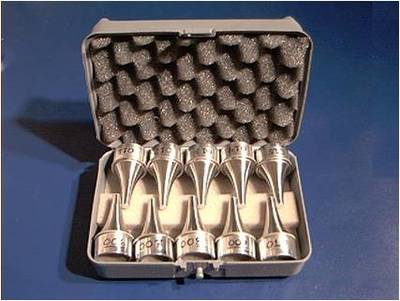

Gould / Westinghouse Ocean Systems - MK48 / ADCAP / MK50 Torpedo Acoustic Transducers and Arrays

Insulet - Personal Insulin Dispensing Systems

Kodak Inkjet Systems - Piezoelectric Printhead Assembly and Component Process Improvements

Litton Marine Systems - Transducer Testing, Failure Analysis and Assembly Process Improvement

Medtronics (Minneapolis) - Pacemaker and Defibrilator Sensors

Medtronics (Ireland) - Intra Arterial Renal Denervation Elements and Assemblies

N.A.S.A - Satellite Mirror Nano Positioning Systems and NextGen Rocket Igniters

National Institute of Health - Support of several SBIR and STTR Initiatives

OmniSonics Medical Technologies – Intravenous and Intra Arterial Plaque Ablation

Private Equity Venture - Developed and Delivered MHz Transducers for Brain Tumor Drug Delivery

Sequenom Genetics - 0.1 Nanoliter DNA Pump Failure Analysis and Corrective Actions

United States Navy - Biofouling Removal and Prevention for Submarine Periscope Windows

Vascor Medical - Product Development for Intravenous Devices

Vermon Medical Imaging - Optimizing Machining of Piezoelectric Materials

Piezo Solutions History with PZT Piezoelectric Materials

The Clevite Ordnance Facility where the first PZT (Lead Zirconate Titanate) Piezoelectric Ceramic Formulations and Materials were developed is still standing in Cleveland Ohio.

This historic site was the home of Don Berlincourt, Bernard Jaffe, Hans Jaffe, Helmut Krueger and William Cook who developed the first synthetic PZT Piezoelectric Ceramic materials between 1955 and 1969.

Clevite sold the Ordnance Division to Gould Inc. in 1969 but maintained a Piezoelectric Production facility in Bedford, Ohio. Bernard Jaffe transferred employment to Clevite at the Bedford, Ohio facility. Hans Jaffe and Helmut Kreuger were transferred to Gould Laboratories in Rolling Meadows, Illinois. William Cook created Cleveland Crystal and Don Berlincourt founded Channel Products in Chesterland, Ohio.

The original laboratories maintained production of piezoelectric ceramic elements for the MK-48 Torpedo Program with a staff of only three people. The facility operated without Engineering Support until 1978 when John Hudak joined Gould Ocean Systems. John provided Engineering and Production Support for the MK-48 and ADCAP Ceramic Element, Acoustic Transducer, and Nose Array Assemblies until 1992. During that time, the original lab operations were moved to Gould Ocean Systems Division at 18901 Euclid Avenue, Cleveland, Ohio.

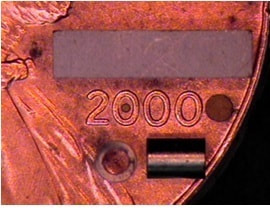

In 1992, John joined Morgan Matroc (previously Clevite and Vernitron Electroceramics) as the Vice President of Operations. During his employment with Morgan, Mr. Hudak realized that customers frequently knew very little about the material. In 2000 John founded Piezo Solutions and has since provided Engineering Design, Product Development and Manufacturing support to more than 450 companies and government agencies.

The original Clevite Labs at East 105th Street have since been repurposed and are currently home to several small businesses.

This historic site was the home of Don Berlincourt, Bernard Jaffe, Hans Jaffe, Helmut Krueger and William Cook who developed the first synthetic PZT Piezoelectric Ceramic materials between 1955 and 1969.

Clevite sold the Ordnance Division to Gould Inc. in 1969 but maintained a Piezoelectric Production facility in Bedford, Ohio. Bernard Jaffe transferred employment to Clevite at the Bedford, Ohio facility. Hans Jaffe and Helmut Kreuger were transferred to Gould Laboratories in Rolling Meadows, Illinois. William Cook created Cleveland Crystal and Don Berlincourt founded Channel Products in Chesterland, Ohio.

The original laboratories maintained production of piezoelectric ceramic elements for the MK-48 Torpedo Program with a staff of only three people. The facility operated without Engineering Support until 1978 when John Hudak joined Gould Ocean Systems. John provided Engineering and Production Support for the MK-48 and ADCAP Ceramic Element, Acoustic Transducer, and Nose Array Assemblies until 1992. During that time, the original lab operations were moved to Gould Ocean Systems Division at 18901 Euclid Avenue, Cleveland, Ohio.

In 1992, John joined Morgan Matroc (previously Clevite and Vernitron Electroceramics) as the Vice President of Operations. During his employment with Morgan, Mr. Hudak realized that customers frequently knew very little about the material. In 2000 John founded Piezo Solutions and has since provided Engineering Design, Product Development and Manufacturing support to more than 450 companies and government agencies.

The original Clevite Labs at East 105th Street have since been repurposed and are currently home to several small businesses.

Piezo Solutions

10072 Crows Nest Cove

Aurora, Ohio 44202

Phone: (216) 406-2045

Email: piezosolutions@outlook.com

10072 Crows Nest Cove

Aurora, Ohio 44202

Phone: (216) 406-2045

Email: piezosolutions@outlook.com